Industry 4.0 with Datalogger 2

Automatic film sealing and release clamp

MOTORIZED PRE-STRETCH with 1 or 2 motors

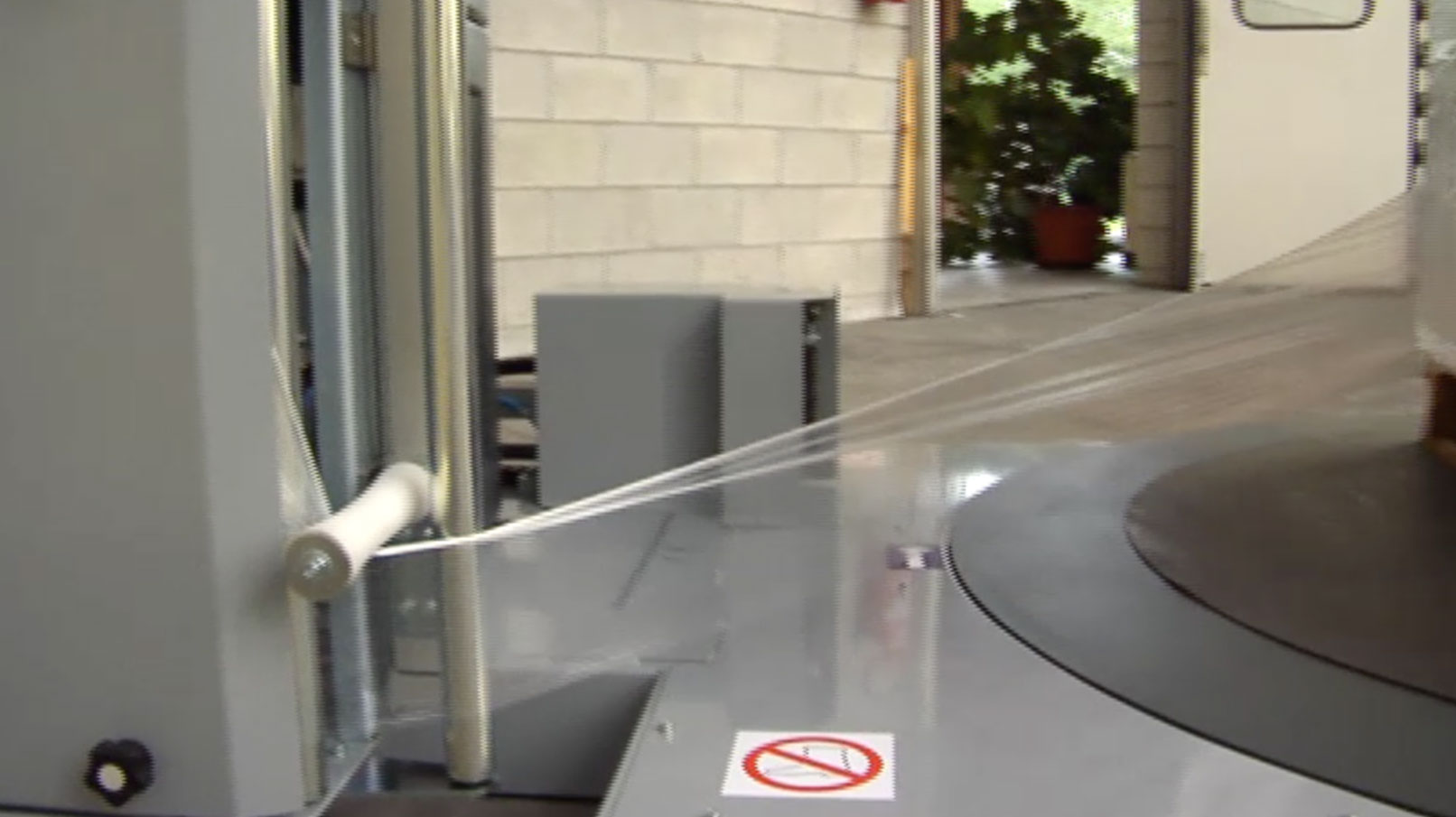

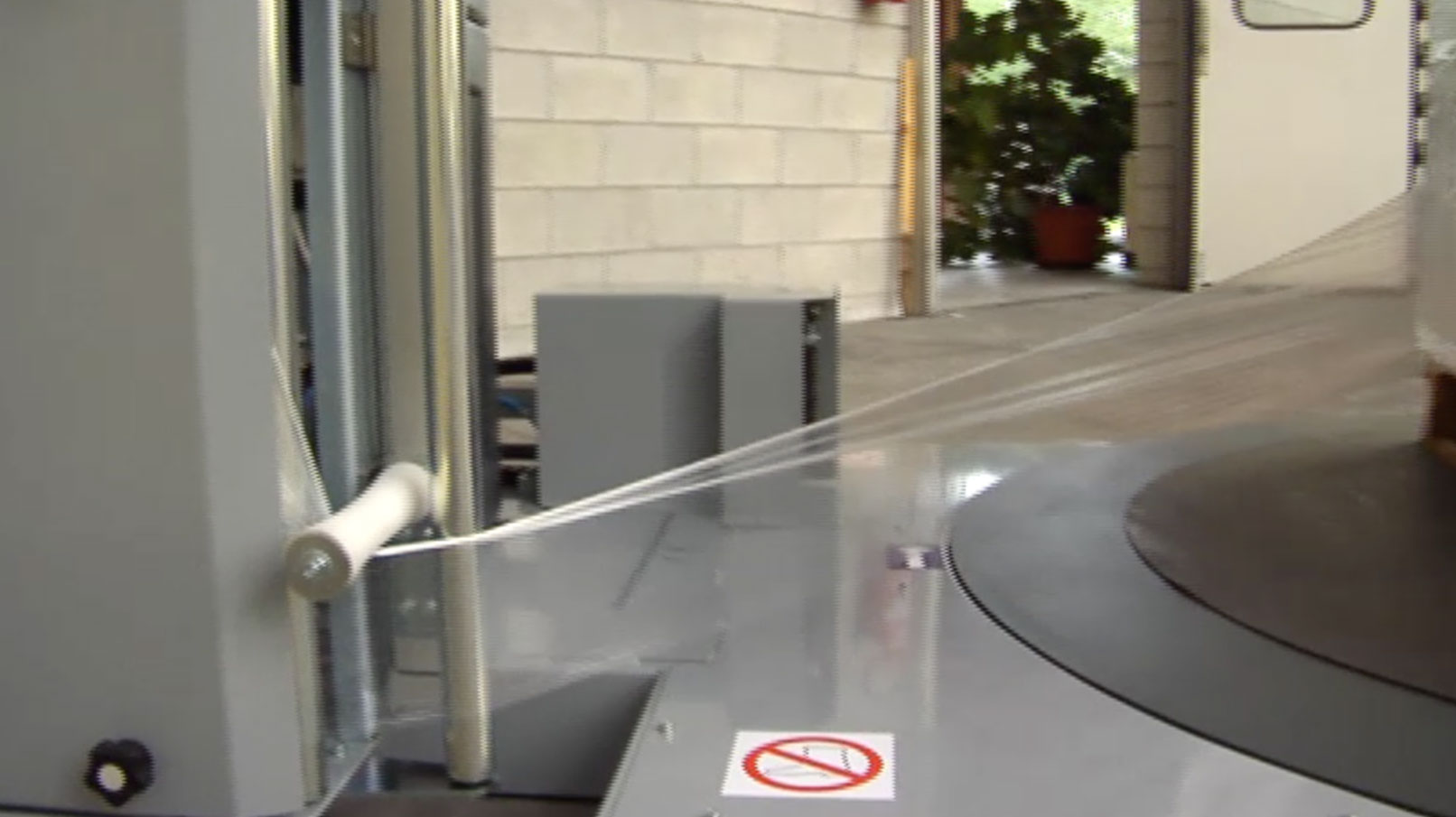

Film reduction to cord for better anchoring to the pallet

Programmable reinforcement wraps in different positions

Industry 4.0

Datalogger2 remote control and management system

ON REQUEST

Double TOUCH-SCREEN control panel

Scale under the rotating table to detect the weight of the product

Volumetric detection of the product

Pictures before and after the wrapping process

Cycle start with radio control

Rotating table 1800 mm

Stabilising top press

Designed and developed to collect the data produced by the new machines with the latest generation control panel in real time on a Cloud platform. The data is collected, processed and shared to monitor production, performance, consumption, machine status and produce statistics.

DESIGNED AND PRODUCED BY EFFE3TI

Semiautomatic wrapping machine with rotating turntable.

Pallet wrapper equipped with a film cutting and sealing system at the end of the cycle. Motorized pre-stretch for maximum savings in consumables, available in versions with 1 or 2 motors, with savings of up to 400%.

SPECIFICATIONS

- Standard pre-stretch up to 300%; on request with two motors up to 400%

- Distance between column and rotary table 500 mm

- Wrapping height up to 2600 mm detected by photocell

- Separate programming of high and low reinforcement wraps

- Table rotation regulated by inverter from 5 to 15 rpm

- Table stop position controlled by sensor

- Variable speed of movement of the carriage customizable

- Film carrier fall prevention system

- Work cycles controlled by PLC and electronic board

- Reduction of the film band for greater anchoring to the pallet

- Automatic system of stapling – cutting – sealing of the final edge of the film