Imagine a normal manual packaging line, where one or more operators are engaged in a repetitive series of operations

- fill up boxes (maybe different boxes with different products),

- close with adhesive tape,

- weigh the boxes,

- stick the label with all the information necessary for shipping,

- pass the boxes under a strapping machine to seal it,

- accumulate the boxes somewhere to be shipped.

If you think about it, a series of operations of this type inevitably brings with it a lot of downtime. If you then add the possibility that an operator gets distracted for any reason we must also consider a certain percentage of error in the operations.

HOW MANY OPERATORS DO YOU NEED?

HOW LONG DOES IT TAKE?

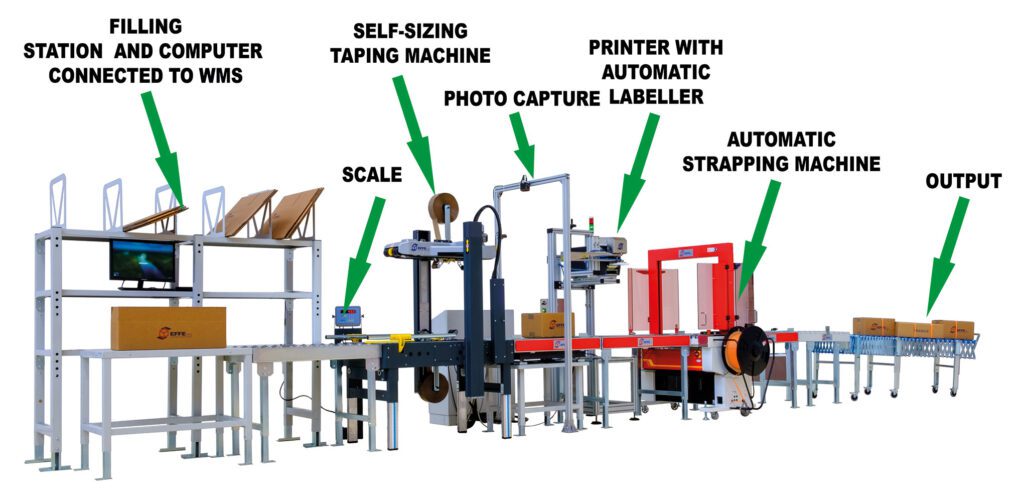

Everything can be improved and we did it with this AUTOMATIC LINE 4.0.

- the operator fills the boxes of different sizes with the necessary products

- the box is pushed towards the scale … and from this moment until the end of the cycle everything is automatic.

Investing in technology makes life easier … and it also makes it safer.

Here is the sequence of operations of which you won't have to worry anymore

The box passes on rollers in which a scale is integrated that reads its weight.

The taping machine automatically measures itself on the box and closes it with adhesive tape.

A picture of the box is taken and archived on the WMS.

A bar code reader detects the type of product boxed and couples it with the information of the scale, communicating with the company’s management system which returns all the data necessary to produce the label.

The printer receives all the data from the management system (customer data, product characteristics, number of packages per order, weight of the package … and any other necessary information) and prints the label that is glued to the box as it passes.

An automatic strapping machine provides to seal with strap the package that will arrive at the end of the line through the motorized rollers.

A pusher sends the boxes to the accumulation part from where they will be taken and then shipped.