CUSTOMIZABLE for your Company

Film carrier with 1- or 2-motors PRE-STRETCH

TOUCH-SCREEN control panel

Work cycle programming

Variable film carrier and arm speed

Pallet height detected by photocell

Wrapping height on request

0

Standard wrapping height

0

Up to 3 years warranty

0

Standard pallet dimensions 1200×1200

Sensor controlled rotation stop

ON REQUEST

Automatic film cut at the end of the cycle

Photocell for black or reflecting products

Motorised or pneumatic top press

Designed and developed to collect the data produced by the new machines with the latest generation control panel in real time on a Cloud platform. The data is collected, processed and shared to monitor production, performance, consumption, machine status and produce statistics.

DESIGNED AND PRODUCED BY EFFE3TI

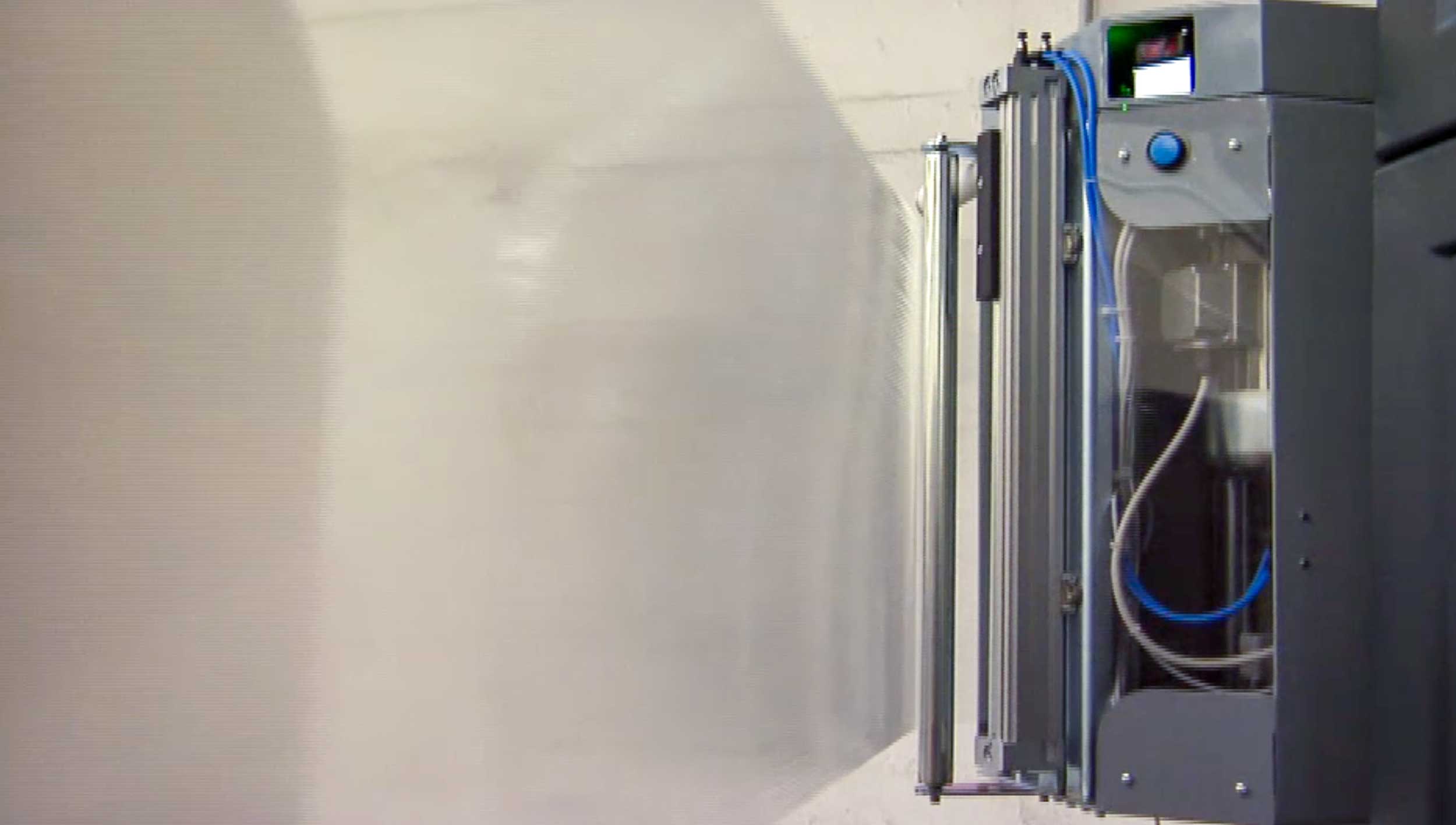

Semi-automatic wrapping machine with rotating arm, with motorized pre-stretch for the best use of the stretch film on the product and latest generation Touch Screen control panel.

Wrapping machines with rotating arm offer higher productivity (pallets / hour) than wrapping machines with rotating table.

SPECIFICATIONS

- Equipped with motorized pre-stretch that allows a significant saving of film used: up to 300% in the standard version and up to 400% in the “Dual motor” version.

- The machine has 10 password protected programs with Touch-screen control panel.

- The standard model is designed for wrapping, with stretch film, pallets with dimensions up to 1200 x 1200 mm with unlimited load capacity.

- Standard machine pallet height h = 2100mm detected by photocell; on request special heights up to 3000 mm

- The rotation speed of the arm is regulated by an inverter (adjustable rotation from 4 to 15 rpm)

- Arm stop position controlled by sensor

- Speed of the customizable reel-holder trolley regulated by inverter

- Siemens Touch Screen Control Panel

- Anti-fall system of the film carrier