Longer battery life: over 4000 charge/discharge cycles

No memory effect

Operating time increased by more than 50%

TOUCH-SCREEN control panel

Feed SPEED adjustment up to 1.1 m/s with soft start/stop

ADVANCED PROGRAMMING of work cycles

PATENTED TRACTION AND DRIVE SYSTEM

Manual movement with buttons on rudder

Hinged column for transport

Why choose the new version?

- 2 years warranty on the machine and 2 years warranty on the battery

- Longer battery life: over 4000 charge/discharge cycles

- No memory effect: possibility of charging a partially discharged battery without compromising its lifespan

- Increased operating autonomy* over the 50% to allow working for extended periods without stopping for charging

- Reduction of maintenance costs

- No performance degradation during use

- Full charge time between 2 and 2.5 hours

1000mm clearance from pallet

Adjustable speed

Flashing and sound signal

ON REQUEST

PHOTOCELL FOR BLACK PRODUCTS

SAFETY LASER SCANNER

AUTOMATIC CUTTING (mod. V5)

DESIGNED AND MADE BY EFFE3TI

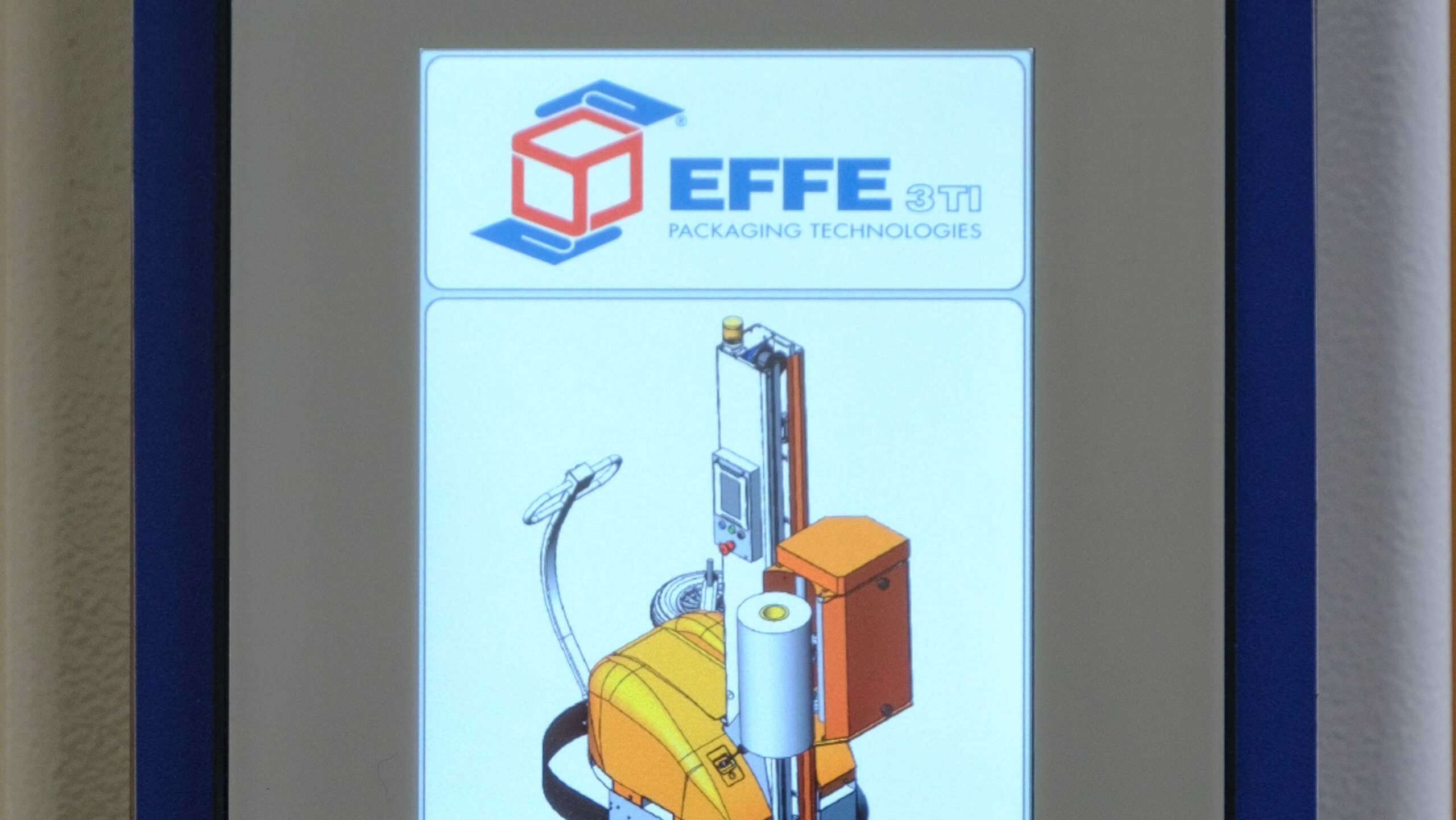

If the product is not loaded on the winder, the winder moves around the product. OSCAR is designed for versatility and mobility needs, where immediate wrapping of the product “on site” is needed, with battery life of up to 250 packs.

It can be moved effortlessly thanks to the handlebar equipped with movement buttons or, thanks to the special housings, transported with forklifts.

TECHNICAL FEATURES

- Dimensions WxLxH: 690x1060x2100 mm

- Clearance of 1000mm from the pallet during the wrapping cycle

- Minimum package: 600mm x 600mm

- Battery life per charge: over 250 packs (W800x1200xH1500)

- Full charge cycle: 8 hours (on-board charger)

- Motion flashing and cycle start and end sound signal

- Column height H: 2100mm

- Weight 250Kg at working speed

- Winding height detected by photocell

- Feed speed adjustment up to 1.33 m/s with soft start/stop

- Speed adjustment of the reel carriage from 3 to 5 m/min.

- Separate top and bottom reinforcement rounds

- Reinforcement rounds with “step” cycle

- Adjustment of the up and down speed of the reel holder

- Separate film tension adjustment for each cycle position

- Intermediate reinforcement with setting of the height and number of turns

- Manual movement with buttons on rudder

- Hinged column for transport

- Forkable from the side and rear

- Model V.5 — Standard 200% motorized pre-stretch reel holder (100%, 150%, 250% ratios on request)

- Model V.3 — Reel holder with electromagnetic brake for tensioning the stretch film

- Model V.1 — Reel holder with mechanical brake for tensioning the stretch film

- End of film and film breakage reporting

- Battery charge signal

- Touch-screen control panel