Italtin, in the province of Bergamo, is an important company that produces a wide range of lithographed and personalized tin boxes. The production is extremely varied and for shipping it is necessary to wrap the pallets with stretch film in a reliable and safe way. The sizes and shapes of the boxes are of all types, sometimes with rounded or pointed edges.

Reel holder with MOTORIZED PRESTRETCHING 1 or 2 MOTORS

It allows to wrap light and unstable products that would not be wrapable with traditional systems. The stretch film is dispensed in the right quantity by rollers driven by a motor controlled by an electronic system that measures the speed and keeps the tension of the film constant over the entire wrapped product.

The motorized pre-stretching system ensures variable stretching up to 400% in the 2-engine version.

Winding height detected by photocell

SPEED adjustment of the reel carriage

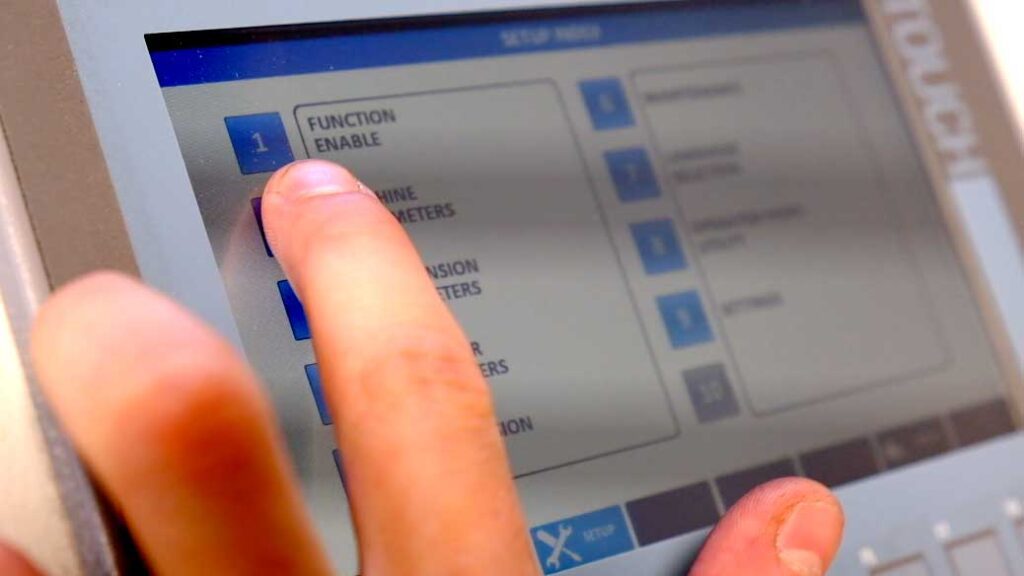

Separate control panel with panel TOUCH SCREEN

Separate programming of high and low reinforcement rounds

Arm rotation regulated by inverter from 4 to 15 rpm

TECHNICAL SPECIFICATIONS

- Equipped with motorized pre-stretch which allows significant savings in film used: up to 300% in the standard version and up to 400% in the “Dual motor” version.

- The machine has 10 password protected programs with touch-screen control panel.

- The standard model is designed for wrapping, with stretch film, pallets with dimensions up to 1200 x 1200 mm with unlimited load capacity.

- Standard machine pallet height h=2100mm detected by photocell; special heights up to 3000 mm on request

- The rotation speed of the arm is regulated by an inverter (rotation adjustable from 4 to 15 rpm)

- Sensor controlled arm stop position

- Customizable reel carriage speed regulated by inverter

- Siemens Touch Screen Control Panel

- Anti-fall system of the reel trolley