For AUTOMATIC LINES of packaging

TAILORED FOR YOUR BUSINESS

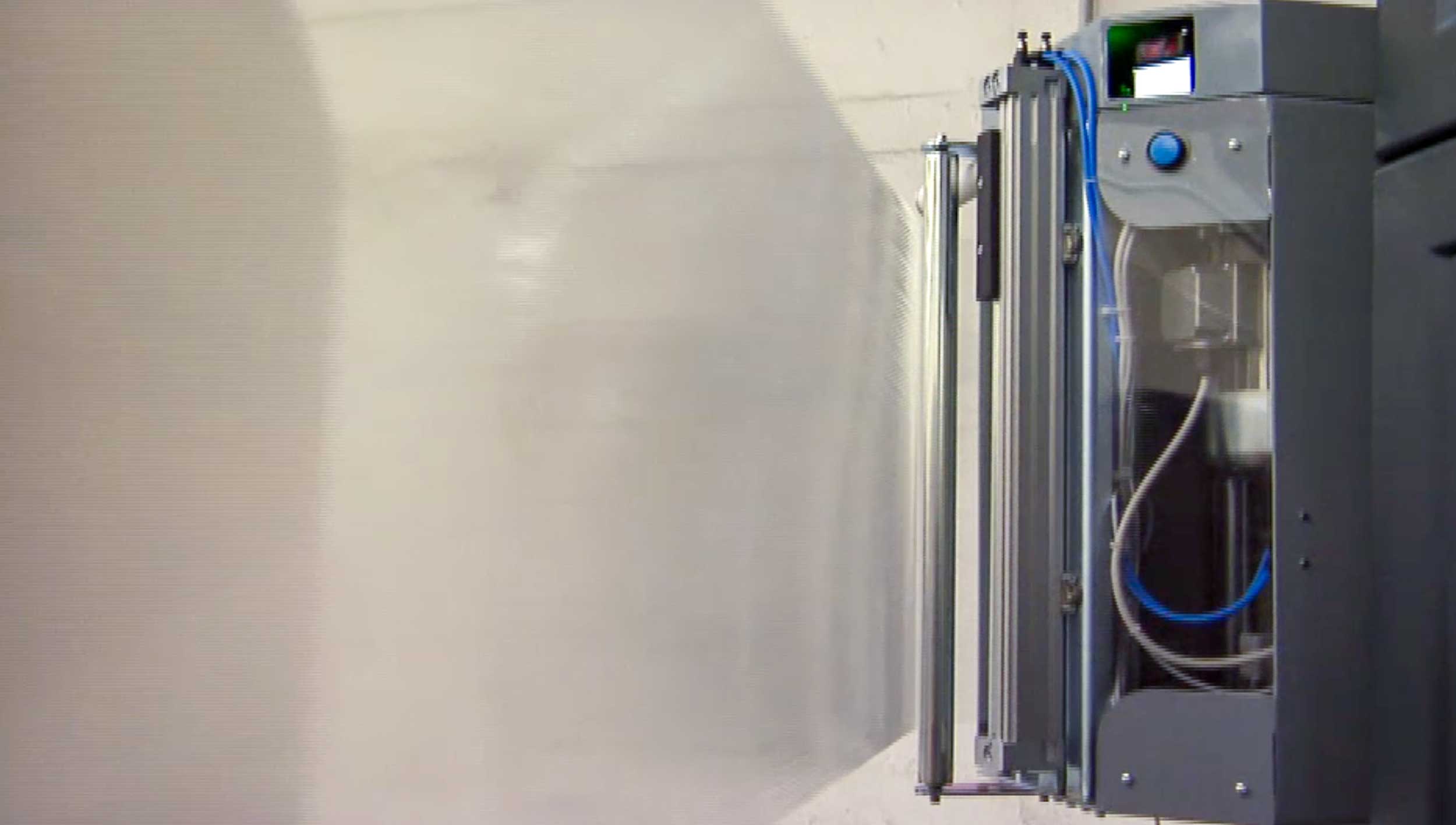

Reel holder with MOTORIZED PRESTRETCH with 1 or 2 motors.

TOUCH-SCREEN control panel

Adjustable table, trolley and roller speed

AUTOMATIC film clamping and cutting system

ON REQUEST

Protective nets and barriers

Automatic film welder

Integration with other machines

The use of advanced management systems, the ease of use of our programs thanks also to the Touch-Screen control panel, the possibility of integrating the wrapping machine with multiple additional devices and optionals make us sure that we can cover most of your needs.

DESIGNED AND MADE BY EFFE3TI

Automatic turntable wrapping machines (also called pallet wrappers or pallet wrappers) are machines for applying stretch film on pallets of products in a completely automatic way, without any operator intervention.

The automatic machine is designed and built to be integrated into automatic wrapping lines, where the formed pallets are automatically transported to the wrapping machine (usually located at the end of the production line), wrapped according to the parameters set in programs, and finally expelled towards the last end of the production line where they will then be picked up for loading onto trucks and transport to their final destination.

The correct use of consumables is ensured by the device called “motorized pre-stretch” which allows maximum film saving and the correct stabilization tension for palletized products, regardless of their shape or weight.

The materials used, the conformation of the line and all the accessory products are studied on the basis of the customer's production needs.

TECHNICAL SPECIFICATIONS

The standard model is designed for wrapping, with stretch film, pallets with dimensions up to 1200 x 1200 mm with a load capacity of 2000 kg.

- Pallet height detected by photocell

- Table rotation speed regulated by inverter (adjustable rotation from 5 to 15 rpm)

- Sensor controlled table stop position

- Customizable reel carriage speed regulated by inverter

- Anti-fall system of the reel trolley

- Automatic film clamping and cutting system

- 1 or 2 motor film pre-stretch

- Touch-Screen Control Panel