With CUTTING and WELDING film automatic

Automatic film welding and release clamp

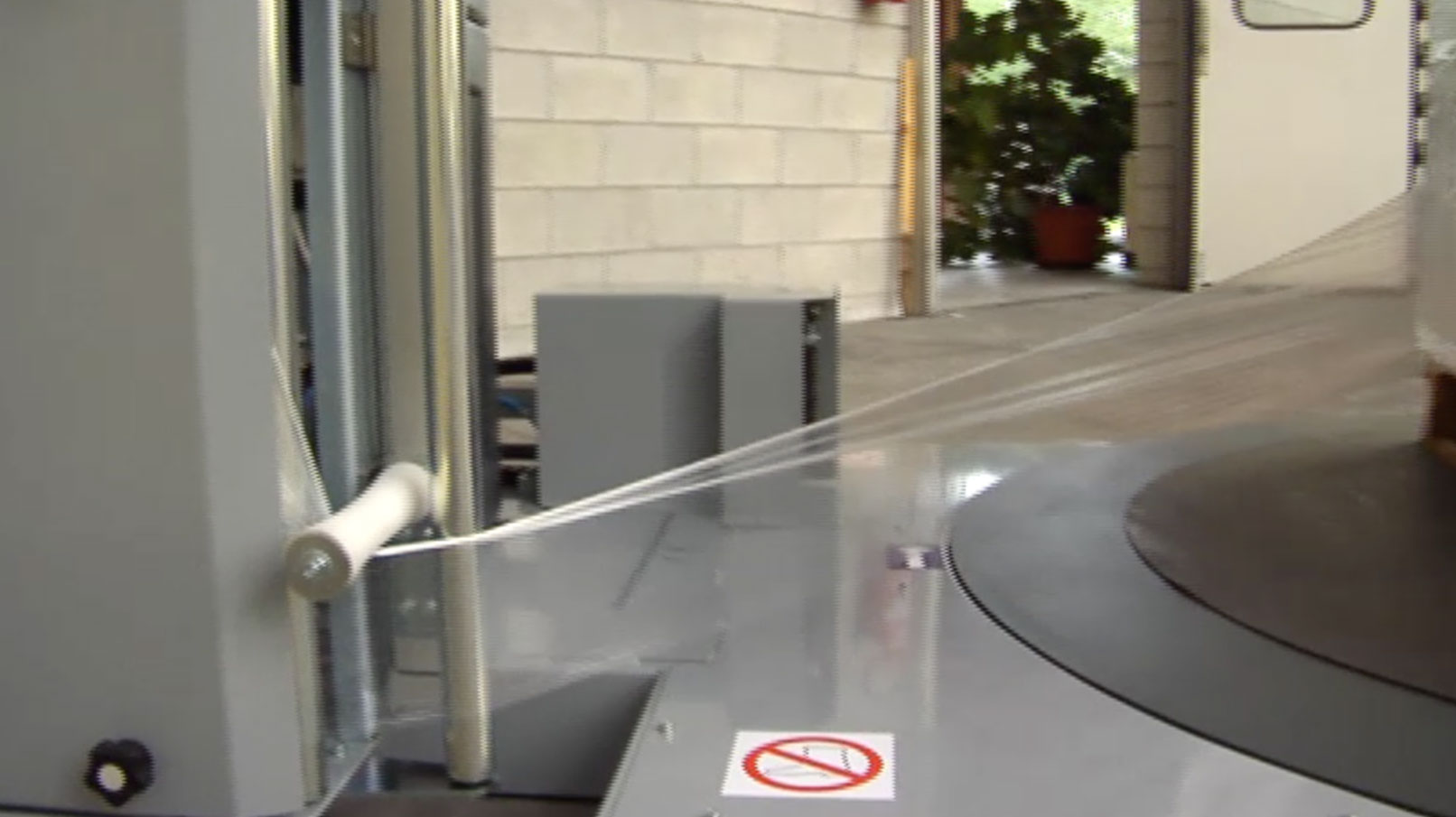

Reel holder with MOTORIZED PRESTRETCH with 1 or 2 motors.

TOUCH-SCREEN control panel

Customizable work programs

Adjustable table and carriage speed

Reduction of the film band for better anchoring to the pallet

Anti-fall device on the reel trolley

Winding height on request

0

Load capacity kg

0

Up to three years warranty

0

ON REQUEST

Motorized or pneumatic stabilizing press

Cycle start with radio control

Rotary table 1800 mm

Designed and developed to collect in real time on a Cloud platform the data produced by the new machines with a latest generation control panel. Data is collected, processed and shared to monitor production, performance, consumption, machine status and produce statistics.

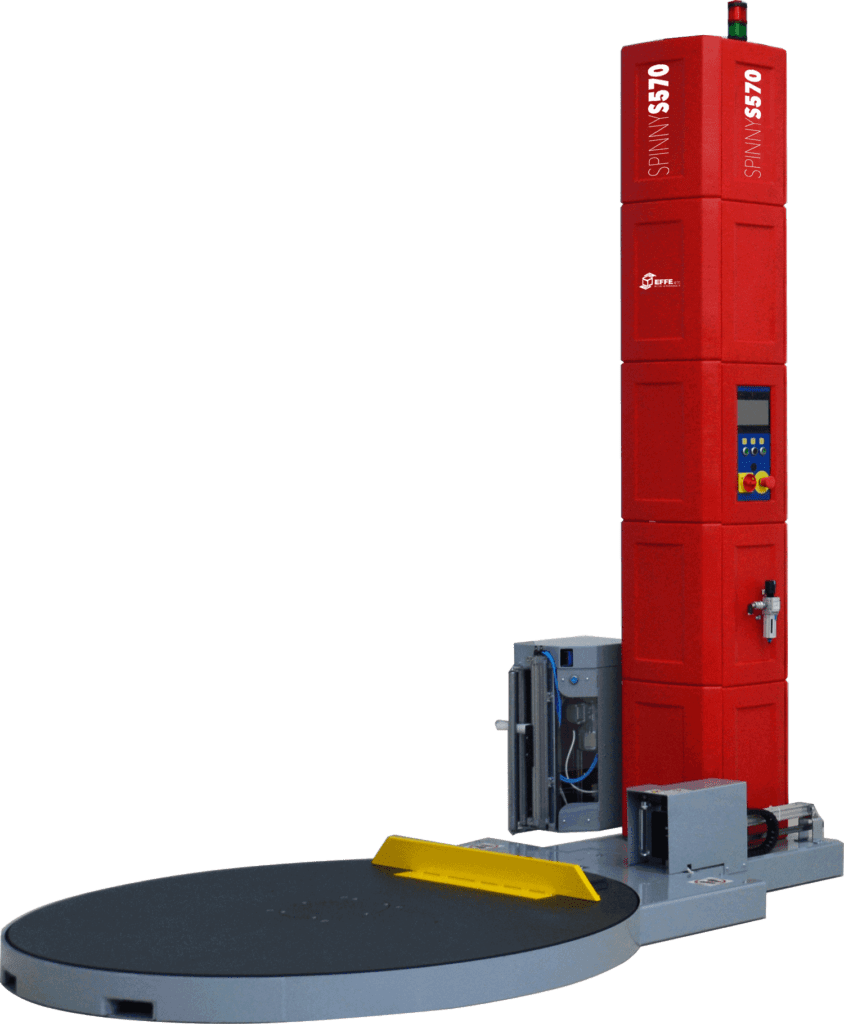

DESIGNED AND MADE BY EFFE3TI

Semi-automatic wrapping machine with rotating table.

Pallet wrapper equipped with a film cutting and welding system at the end of the cycle. Motorized pre-stretch for maximum savings in consumables, available in 1 or 2 motor versions, with savings of up to 400%.

TECHNICAL SPECIFICATIONS

- Standard pre-stretch up to 300%; on request with two motors up to 400%

- Distance between column and rotary table 500 mm

- Wrapping height up to 2600 mm detected by photocell

- Separate programming of high and low reinforcement rounds

- Table rotation regulated by inverter from 5 to 15 rpm

- Sensor controlled table stop position

- Customizable variable carriage movement speed

- Anti-fall system for reel trolley

- Work cycles controlled by PLC and electronic board

- Reduction of film band for better anchoring to the pallet

- Automatic stapling – cutting – sealing of the final edge of the film

- Voltage: 230 V single phase On request, 400-415 V three phase

- Frequency: 50 Hz

- Installed power: 3 kW

- Auxiliary power supply: 24 V DC